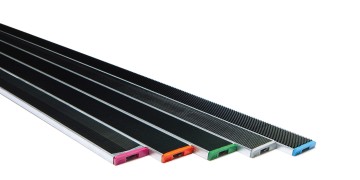

Groz-Beckert Carding offers a complete range of high quality card clothing for short staple applications. The range contains blow room, feed roller, cylinder,doffer and licker-in wires as well as flexible tops, stationary flats and cleaning fillets. The product range covers a very wide range suitable for all carding machine types and applications used in today’s textile industry. Groz-Beckert Carding offers its technical support to specify card clothing considering card model and application to allow the customer to achieve the optimum performance in terms of carding and spinning quality as well as lifetime of the card clothing.

The portfolio includes card wires and clothings for the short staple and long staple spinning industry and for the nonwovens industry.

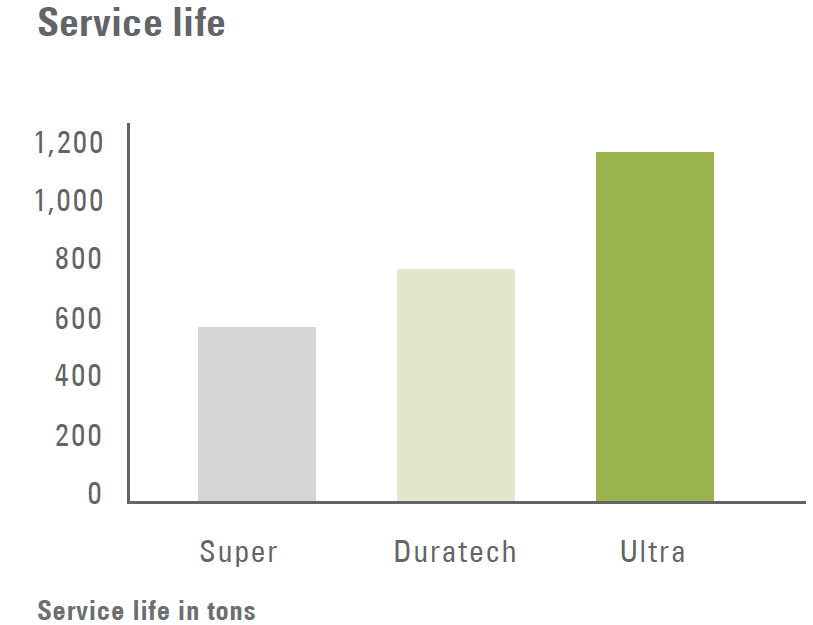

Super is a high carbon steel, the standard product for low production cards with lifetime of up to 600 tons for cylinder wire.

Duratech is a micro-alloyed steel for higher wear resistance properties which is recommended for higher quality requirements in terms of carding consistency and for longer lifetime.The lifetime for cylinder wires is up to 800 tons.

Ultra is the high-end steel grade for the highest wear resistance properties and lifetime. Lifetime of cylinder wire is up to 1,200 tons. Ultra steel is recommended for for the latest generation cards where the highest card production rates are achieved.

Products:

Blowroom wires

Raw materials arrive at spinning mills in compressed bales. They are opened and cleaned in the blowroom, which subjects the material to high stress.

Feed roller wires

This wire is responsible for uniform feeding of fibers into the card. Coarse interlocked wire is usually used to control thick fiber mats.

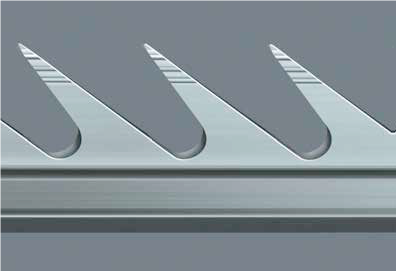

Licker-in wires

The licker-in’s task is to open the fiber tufts and prepare them for the carding process.

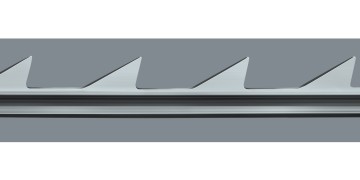

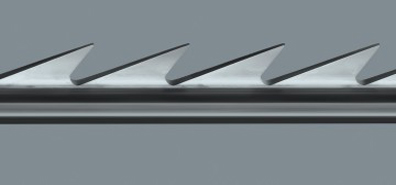

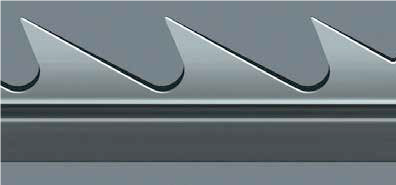

Cylinder wires

Together with the revolving flats and stationary carding elements in the pre and post carding zone, the cylinder is responsible for main carding action and fiber separation.

Doffer wires

The doffer wire takes over the fibers from the cylinder. A high rate of fiber transfer should be reached in addition to gentle and uniform web transfer.

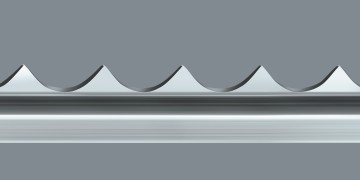

Revolving tops

Revolving tops consists of flexible wires which, along with the cylinder, take on the main carding action. In addition to carding, tops are designed to collect trash, dust and short fibers.

Stationary flats and stationary flat systems

Stationary flats in the pre and post carding zone, along with the revolving tops, provide for additional carding.

Cleaning fillets

Cleaning fillets are used for cleaning rollers for stripping rollers and for revolving tops.

Stripping roller wires

The stripping wire strips the web from the doffer wire. Web transfer should be gentle without forming thick places. Only then uniform yarn can be produced.

Border wires

Border wires are necessary to securely fasten the beginning and the end of card wires onto a roller and are embedded in the grooves at the edge of the rollers.