00

Groz-Beckert entered the weaving segment in 2000 with the acquisition of the Swiss company Grob Textile AG and has been offering weaving machine accessories since that time. Today the weaving product range includes over 12,000 individual items. On the basis of broad range of accessories and systems, GROB textile AG supplies not only weaving machine producers but also weaving centers all over the world . This includes heald frames, healds, drop wires and warp stop motions. That adds up to more than 12.000 products. And the result is a broad range of end product, from woven textiles for the clothing industry and household textiles to technical textiles.

Wherever the production of textiles fabric that are thick or that have sensitive warp stops is involved, the technical competence of GROB comes into its own. Numerous patents and continual development processes with regard to heald frames and healds guarantee optimal performance and economic efficiency. But even in the volume market, where production of simpler materials with maximum performance is the central topic, the international markets are fully served. In other words: GROB provides the right accessories for every single weaving machine in existence.

The principle behind weaving has proven itself over thousands of years. Even today, warp and weft threads are crossed at right angles to each other.

Warp threads are those which run lengthwise in the fabric, while weft is the transverse thread.

The pattern resulting from this crossing is called weave. A standard weave is plain weave, in which each weft thread runs alternately over and under the warp yarns. Many more patterns and pattern derivatives are possible with other weaves.

From light and open to heavy and dense fabric, patterning possibilities are endless. Depending on fiber and weave, a wide variety of textiles for different applications can be constructed.

- Fabrics for clothing textiles

Clothing is by far the largest market for woven fabric. Shirts, pants, shoes, protective and clean-room clothing are just a few examples of woven textiles with different features.

- Fabrics for home textiles

Many home textiles such as curtains, carpets and upholstery are constructed with very different types of weaves. Special jacquard technology is often used here for patterning.

- Woven fabric for technical textiles

Woven fabrics for the automotive industry, textile construction, facades, interior decoration and logistics are finding more applications. Such high-tech fabric is subject to specific requirements for high tensile strength and elongation.

Whether heald frames, healds, drop wires, warp stop motions, and products for leno weaving in the area of weaving accessories or knotting machines and frames, cleaning and drawing-in machines for weaving preparation: Discover Groz-Beckert’s comprehensive offerings for weaving on these pages.

Drop Wires

Drop wires from GROB check each warp stop gently and individually. This guarantees that the weaving machine can be brought to a stop within a fraction of a second at any time if any irregularities occur.

Healds

GROB supplies healds for rider and riderless heald frames. They are all distinctive for their deformation resistance, high polish and high durability with minimal cross-section. They are manufactured from wire rod or the rustproof band steel GROBINOX®. As the thread-guiding element, the patented OPTIFIL® thread eye guarantees economically efficient and gentle textile fabric production.

Healds Frame

ALfix®, ALforfix®, TWIN C Power® and as the latst innovation-ALtop® heald frames all represent value-for-money textile fabric production-especially on state-of-the-art, high-performance weaving machines. An integrated cushioning eyetem for the movement of the healds enables components to be used for far longer without interruption.

Warp Stop Motion

Even at high weaving machine speeds and under the most varied of operating conditions, electrical warp stop motions from GROB ensure precise single-thread supervision. The benefits: higher value added, less personel strain, and less rejected fabric.

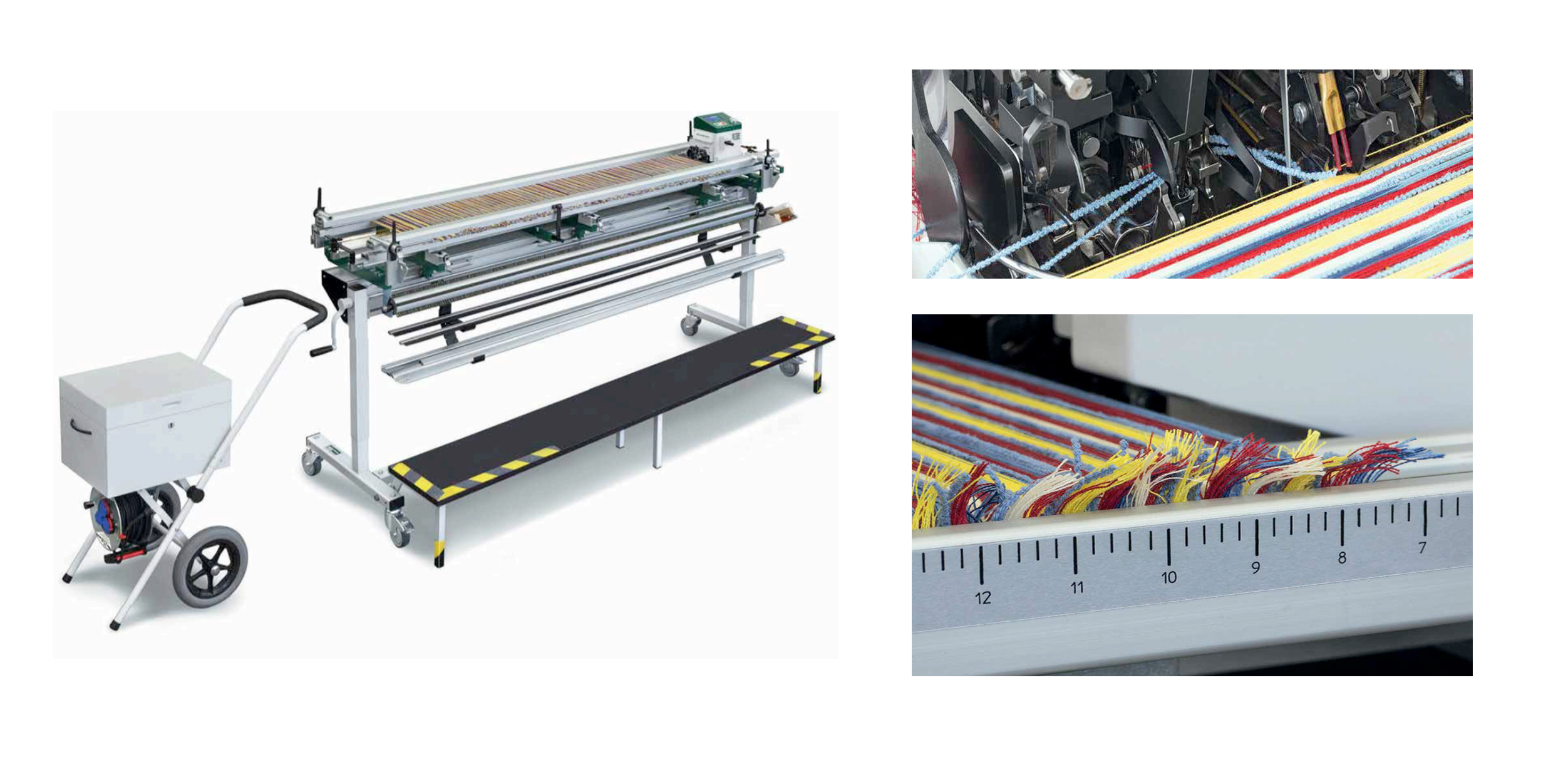

Warp Tying Machine – KnotMaster®

Under the brand name KnotMaster, Groz-Beckert offers high-performance warp tying machines with efficient technology and simple operation for the most diverse range of applications.Customers benefit from rapid warp changes and reduced processing times for more efficient and cost-effective weaving preparation. Different models are available for standard requirements – as well as special applications.