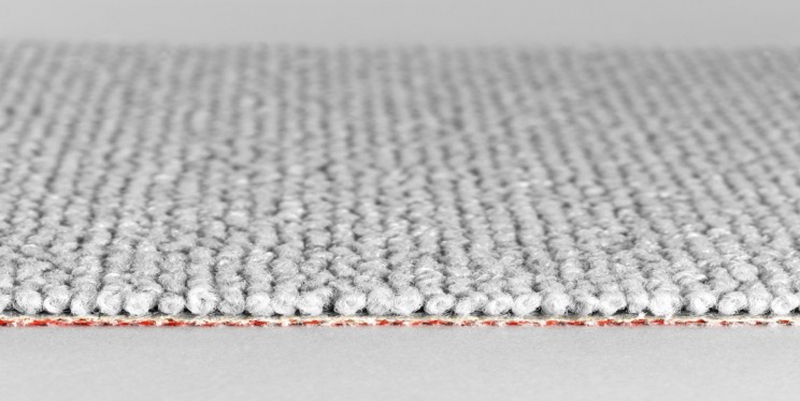

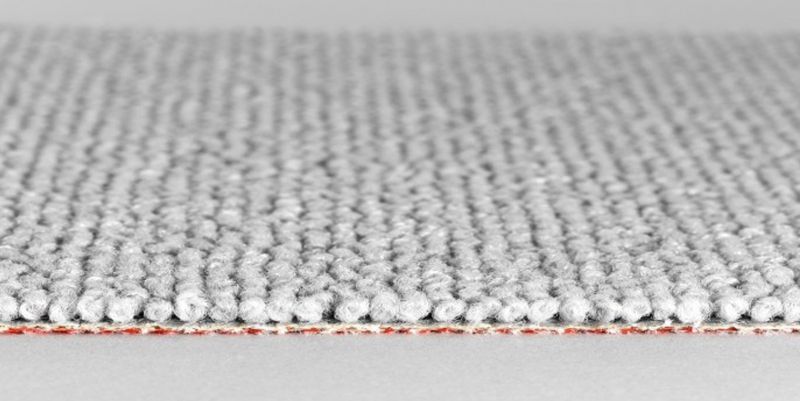

Tufting is a very resent surface production method in the textile industry. Essentially it involves attaching an even and thick pile to textile carrier material. In the end product there is a fundamental differentiation between loop pile goods and velour. Examples include floor covering of various kinds, or automotive application such as side-panel, floor or boot covering.

With total of 2,000 products, Groz-Beckert offers a complete portfolio and responds to trends proactively, from the optimization of breakage resistance and dimensional stability in the materials to the maximization of service life for tufting systems.

Numerous options relating to the multifaceted product range guarantee smooth interplay of needle , looper, reed finger and also knives in the tufting process. Today and in the future, Groz-Beckert is committed to enriching the market with ever more innovations.

Tufting describes a method based on the sewing machine principle. Machine tufting methods use needles to insert the so-called pile yarn into a carrier material. The yarn is fed individually to each of the needles in the needle row, which is the same width as the final product. Then the tufting needles are inserted into the primary backing cloth, a woven or non-woven material. Loopers pick up the yarn before the needles are retracted again. Repeating this process creates a loop pile. Depending on the machine type, the loops can be cut open to create a cut pile. It is also possible to combine loop and cut pile through highly advanced machine, patterning and software components. The carpet types are generally divided into cut pile, loop pile, cut loop and level cut loop.

carpets, high quality interior automotive carpets and artificial turf for sports facilities and landscaping

Products:

Tufting Systems

Groz-Beckert tufting gauge part systems are developed in close harmony with tufting machine builders, raw-material suppliers and users, thereby taking all requirements and experiences into consideration.

Needles and Module Needles

Groz-Beckert needle modules are distinguished by consistently high precision and performance, down to the finest gauges.

Loopers and looper modules

Problem-free and efficient production is guaranteed through the consistent quality and precision of the individual loopers and looper modules.

Reed Finger Modules

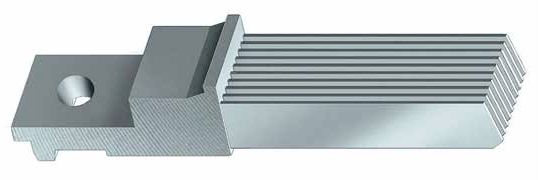

Straight, forked, or in combination: Groz-Beckert offers different models of reed finger modules .

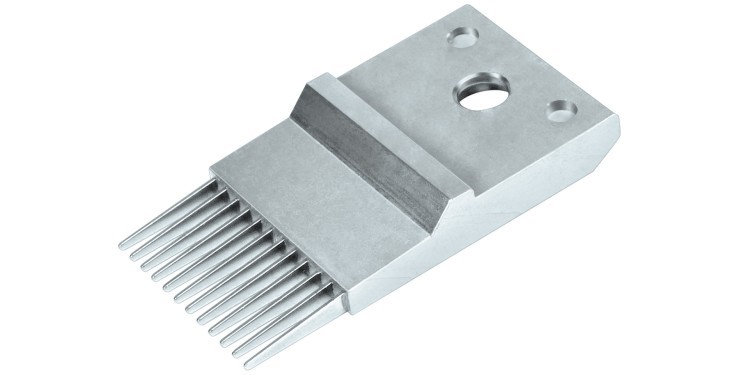

Tufting knives and knife modules

Tufting knives and hard-metal cutting inserts – particularly suited to high-end applications such as automobile carpets.