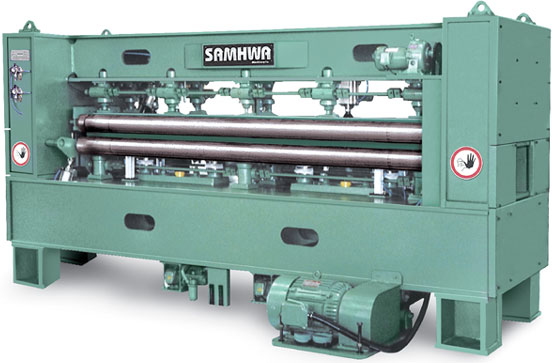

1- Punching mode Down-Stroke Single Board

SHS-DR 2400∼3000

- Working Width : 2400~3000mm

• Needle Beam Stroke / Max stroke frequency – 30mm/1400 s/min

————————————————————— 40mm/1200

————————————————————— 60mm/1000

• Needle per Liner meter : 2000, 3000, 4000, 4500, 5000

▶ Machine Structure

- The needle beam consists of two separate pieces, each piece being connected to one module box, so that it is easy to perform repair or maintenance.

- Power transmission parts, including bearings, within one module box, has their own individual lubricating oil pumps designed to feed oil at constant flow speed and pressure. when one of these pumps fails, the machine stops automatically.

- The machine is installed on the special vibroisolating rubber base to minimize the vibration of the machine. It is also easy to change the installation place of the machine.

▶ Needle Board

- The needle board is made of special aluminum alloy steel and polyurethane, so that it is not deformed and its needle holes do not become loose after use for a long time.

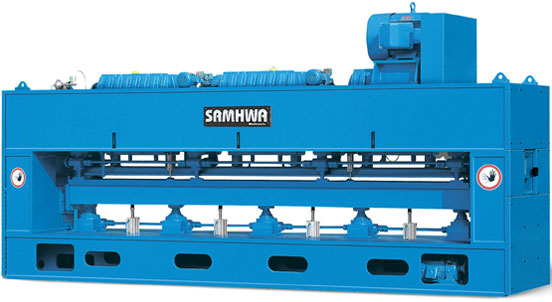

2- Punching mode Up-Stroke Single Board

SHS-UR 2400∼3000

- Working Width : 2400~3000mm

• Needle Beam Stroke / Max stroke frequency – 30mm / 1400 s/min

————————————————————— 40mm / 1200 s/min

————————————————————— 60mm / 1000 s/min

• Needle per Liner meter : 2000, 3000, 4000, 4500, 5000

▶ Machine Structure

- The needle beam consists of two separate pieces, each piece being connected to one module box, so that it is easy to perform repair or maintenance.

- Power transmission parts, including bearings, within one module box, has their own individual lubricating oil pumps designed to feed oil at constant flow speed and pressure. when one of these pumps fails, the machine stops automatically.

- The machine is installed on the special vibroisolating rubber base to minimize the vibration of the machine. It is also easy to change the installation place of the machine.

▶ Needle Board

- The needle board is made of special aluminum alloy steel and polyurethane, so that it is not deformed and its needle holes do not become loose after use for a long time.

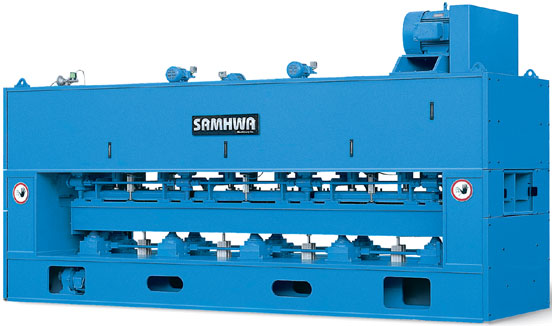

3- Punching mode Down-Stroke Single Board

SHS-DR 3400∼6000

- Working Width : 3400~6000mm

• Needle Beam Stroke / Max stroke frequency – 30mm / 1200 s/min

————————————————————— 40mm / 1100 s/min

————————————————————— 60mm / 1000 s/min

• Needle per Liner meter : 2000, 3000, 4000, 4500, 5000

▶ Machine Structure

- The needle beam consists of three or four separate piece, each piece being connected to one module box, so that it is easy to perform repair or maintenance.

- Power transmission parts, including bearings, within one module box, has their own individual lubricating oil pumps designed to feed oil at constant flow speed and pressure. when one of these pumps fails, the machine stops automatically.

- The machine is installed on the special vibroisolating rubber base to minimize the vibration of the machine. It is also easy to change the installation place of the machine.

▶ Needle Board

•The needle board is made of special aluminum alloy steel and polyurethane, so that it is not deformed and its needle holes do not become loose after use for a long time.

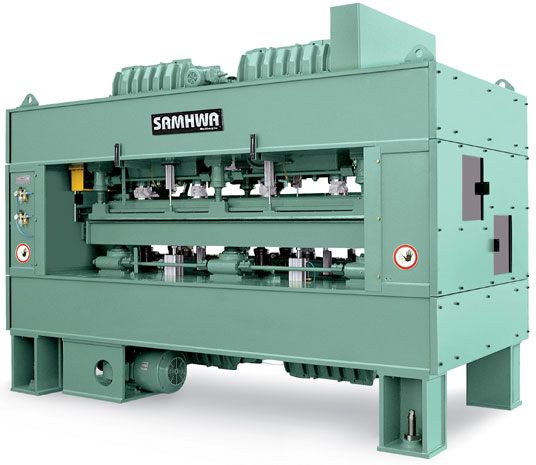

4- Punching mode Up-Stroke Single Board

SHS-UR 3400∼6000

- Working Width : 3400~6000mm

• Needle Beam Stroke / Max stroke frequency – 30mm / 1200 s/min

————————————————————— 40mm / 1100 s/min

————————————————————— 60mm / 1000 s/min

• Needle per Liner meter : 2000, 3000, 4000, 4500, 5000

▶ Machine Structure

- The needle beam consists of three or four separate piece, each piece being connected to one module box, so that it is easy to perform repair or maintenance.

- Power transmission parts, including bearings, within one module box, has their own individual lubricating oil pumps designed to feed oil at constant flow speed and pressure. when one of these pumps fails, the machine stops automatically.

- The machine is installed on the special vibroisolating rubber base to minimize the vibration of the machine. It is also easy to change the installation place of the machine.

▶ Needle Board

- The needle board is made of special aluminum alloy steel and polyurethane, so that it is not deformed and its needle holes do not become loose after use for a long time.

5- Punching mode Down-Stroke Double Board

SHD-DR 2400∼3000

- Working Width : 2400~3000mm

• Needle Beam Stroke / Max stroke frequency – 30mm / 1500 s/min

————————————————————— 40mm / 1300 s/min

————————————————————— 50mm / 1200 s/min

• Needle per Liner meter : 6000, 9000, 10000, 12000

▶ Machine Structure

- The needle beam consists of four separate pieces, each two pieces being connected to two module boxes. These four pieces of the needle beam are designed to be operated up and down with no error by another turning gear box. It is easy to perform repair or maintenance.

- As each module box has a lubricating oil pump. The machine stops automatically when oil pressure drops or when the pump fails.

- The machine is installed on the special vibroisolating rubber base to minimize the vibration of the machine. It is also easy to change the installation place of the machine.

▶ Needle Board

- The needle board is made of special aluminum alloy steel and polyurethane, so that it is not deformed and its needle holes do not become loose after use for a long time.

6- Punching mode Up-Stroke Double Board

SHD-UR 2400∼3000

- Working Width : 2400~3000mm

• Needle Beam Stroke / Max stroke frequency – 30mm / 1500 s/min

————————————————————— 40mm / 1300 s/min

————————————————————— 50mm / 1200 s/min

• Needle per Liner meter : 6000, 9000, 10000, 12000

▶ Machine Structure

- The needle beam consists of four separate pieces, each two pieces being connected to two module boxes. These four pieces of the needle beam are designed to be operated up and down with no error by another turning gear box. It is easy to perform repair or maintenance.

- As each module box has a lubricating oil pump. The machine stops automatically when oil pressure drops or when the pump fails.

- The machine is installed on the special vibroisolating rubber base to minimize the vibration of the machine. It is also easy to change the installation place of the machine.

▶ Needle Board

- The needle board is made of special aluminum alloy steel and polyurethane, so that it is not deformed and its needle holes do not become loose after use for a long time.

7- Punching mode Down-Stroke Double Board

SHD-DR 3400∼6000

- Working Width : 3400~6000mm

• Needle Beam Stroke / Max stroke frequency – 30mm / 1400 s/min

————————————————————— 40mm / 1200 s/min

————————————————————— 50mm / 1000 s/min

• Needle per Liner meter : 6000, 9000, 10000, 12000

▶ Machine Structure

- The machine has three module boxes which are provided with each two pieces of needle beam. These six pieces of needle beam are designed to be operated up and down with no error by another turning gear box.

- It is easy to perform repair or maintenance when a problem is caused within the module boxes.

•As each module box has a lubricating oil pump. The machine stops automatically when oil pressure drops or when the pump fails.

•The machine is installed on the special vibroisolating rubber base to minimize the vibration of the machine. It is also easy to change the installation place of the machine.

▶ Needle Board

- The needle board is made of special aluminum alloy steel and polyurethane, so that it is not deformed and its needle holes do not become loose after use for a long time.

8- Punching mode Up-Stroke Double Board

SHD-UR 3400∼6000

- Working Width : 3400~6000mm

• Needle Beam Stroke / Max stroke frequency – 30mm / 1400 s/min

————————————————————— 40mm / 1200 s/min

————————————————————— 50mm / 1000 s/min

• Needle per Liner meter : 6000, 9000, 10000, 12000

▶ Machine Structure

- The machine has three module boxes which are provided with each two pieces of needle beam. These six pieces of needle beam are designed to be operated up and down with no error by another turning gear box.

- It is easy to perform repair or maintenance when a problem is caused within the module boxes.

- As each module box has a lubricating oil pump. The machine stops automatically when oil pressure drops or when the pump fails.

- The machine is installed on the special vibroisolating rubber base to minimize the vibration of the machine. It is also easy to change the installation place of the machine.

▶ Needle Board

- The needle board is made of special aluminum alloy steel and polyurethane, so that it is not deformed and its needle holes do not become loose after use for a long time.

9- Punching mode Double Side Stroke Single Board

SHS-DUR 2400∼3000

- Working Width : 2400~3000mm

• Needle Beam Stroke / Max stroke frequency – 30mm / 1200 s/min

————————————————————— 40mm / 1100 s/min

————————————————————— 60mm / 900 s/min

• Needle per Liner meter : 2000, 3000, 4000, 4500, 5000

▶ Machine Structure

- The needle beam is divided into a upper piece and a lower piece. These pieces of needle beam connected to two upper and lower module boxes are designed to be operated up and down by separate driving motors.

- In a narrow space, one machine can give high working capacity and efficiency which are equal to those of two units (DR type and UR type).

- However, the machine may have a little vibration caused by two driving motors.

- The machine is installed on the special vibroisolating rubber base to minimize the vibration of the machine. It is also easy to change the installation place of the machine.

▶ Needle Board

•The needle board is made of special aluminum alloy steel and polyurethane, so that it is not deformed and its needle holes do not become loose after use for a long time.

10- Punching mode Double Side Stroke Single Board

SHS-DUR, UDR 3400∼6000

- Working Width : 3400~6000mm

• Needle Beam Stroke / Max stroke frequency – 30mm / 1100 s/min

————————————————————— 40mm / 1000 s/min

————————————————————— 60mm / 800 s/min

• Needle per Liner meter : 2000, 3000, 4000, 4500, 5000

▶ Machine Structure

- The needle beam is divided into three or four upper and lower piece. These pieces of needle beam connected to the module boxes are designed to be operated up and down by separate driving motors.

- In a narrow space, one machine can give high working capacity and efficiency which are equal to those of two units (DR type and UR type).

- However, the machine may have a little vibration caused by two driving motors.

- The machine is installed on the special vibroisolating rubber base to minimize the vibration of the machine. It is also easy to change the installation place of the machine.

▶ Needle Board

- The needle board is made of special aluminum alloy steel and polyurethane, so that it is not deformed and its needle holes do not become loose after use for a long time.

11- Punching mode Down-Stroke Single Board

SHS-PL 2400∼4500

- Working Width : 2400~4500mm

• Needle Beam Stroke / Max stroke frequency – 30mm / 1000 s/min

• Needle per Liner meter : Lamella pitch / needles

————————————- —– —–3mm / 7000 s/min

—————————————— —3.5mm / 6000 s/min

▶ Machine Structure

- One needle beam is connected to one module box. According to the working width, more than two module boxes are connected to each other, and needle beams connected to these module boxes are operated up and down by one main motor. As each module box can be disassembled, it is easy to perform repair or maintenance when a problem is caused.

•The bed plate is assembled with special steel blades spaced at regular lamella pitches(3mm, 3.5mm, 6mm and 7mm), instead of holes. When a blade is broken or damage, it is easy to replace it.

•The machine is installed on the special vibroisolating rubber base to minimize the vibration of the machine. It is also easy to change the installation place of the machine.

▶ Needle Board

•The needle board is made of special aluminum alloy steel and polyurethane, so that it is not deformed and its needle holes do not become loose after use for a long time.