Different Machine, Different Abilities, Different Purpose

Productive, flexible and reliable – simply Stoll. It is a widely known fact that Stoll is always looking to increase the productivity of its machines. This productivity, in addition to flexibility and reliability, is a key element of modern knitting machines.

The well-known rapid carriage reversal point of Stoll machines guarantees short knitting times thanks to the Power-RCR – especially in the case of knitting panels with a high number of short strokes. The convenient height of all important machine elements enables the user to work very ergonomically on a CMS machine.

Features

Take a closer look and discover far more advantages

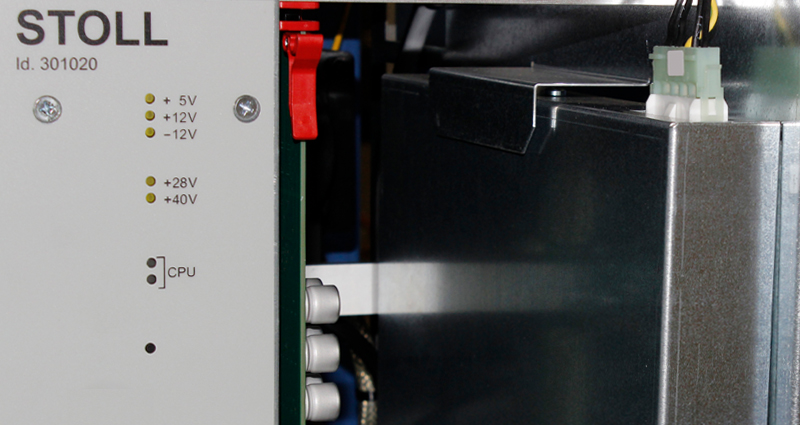

BATTERY BACK-UP

Correct continuation of the knitting process after power failure.

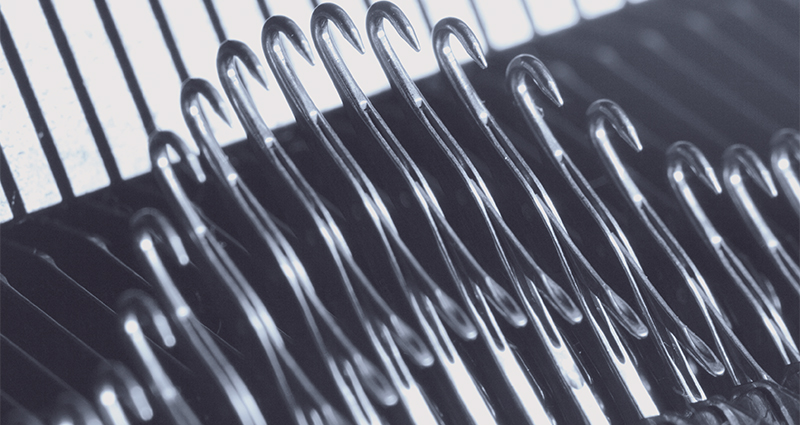

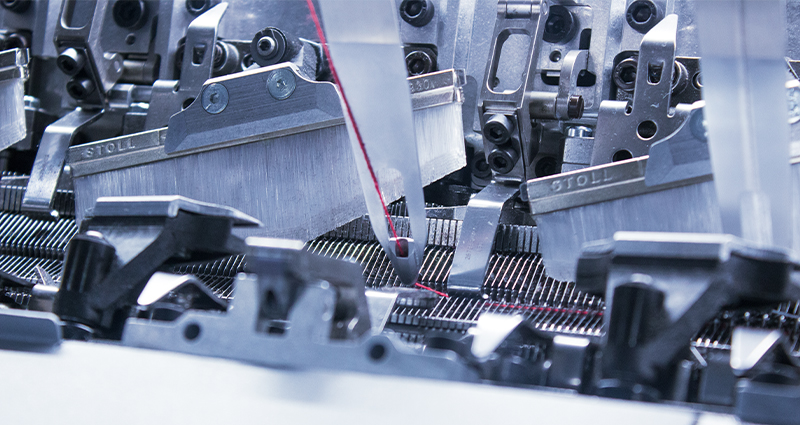

CMS-NEEDLE

The pelerine spring-transfer needle with spring-loaded latch is characterized by low needle wear and a high level of safety during opening, closing, and transferring.

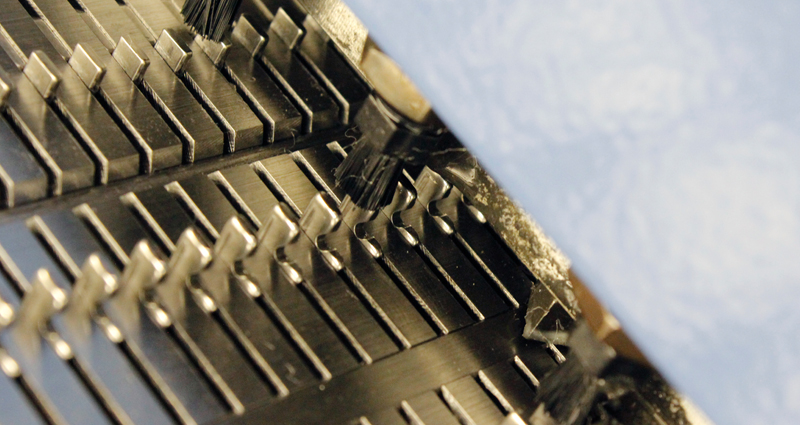

LARGE NEEDLE BED RACKING

The needle bed is equipped with a racking device with a maximum racking course of four inches and a programmable racking speed.

ONLINE VIA NETWORK

With the Ethernet connection CMS-machines from the TC-generation can be connected to standard networks for fast transmission of large quantities of data.

STOLL-TOUCHCONTROL®

The movable (not for 502 models) color display with 800×600 pixels and touch screen (new control generation EKC) is practical and clear and makes pattern changes easy and intuitive.

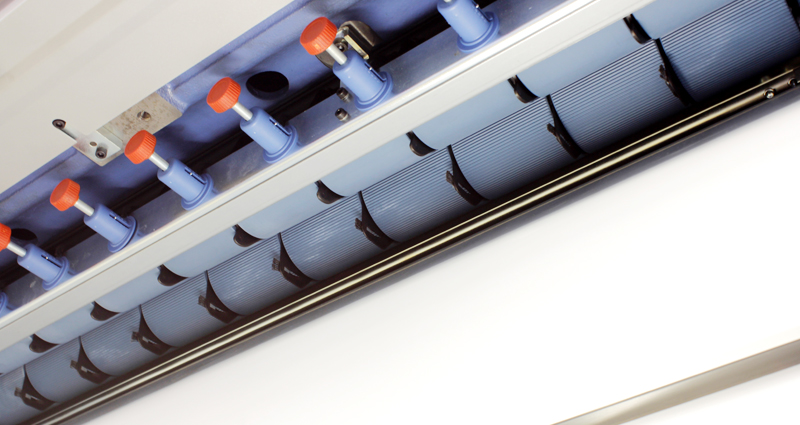

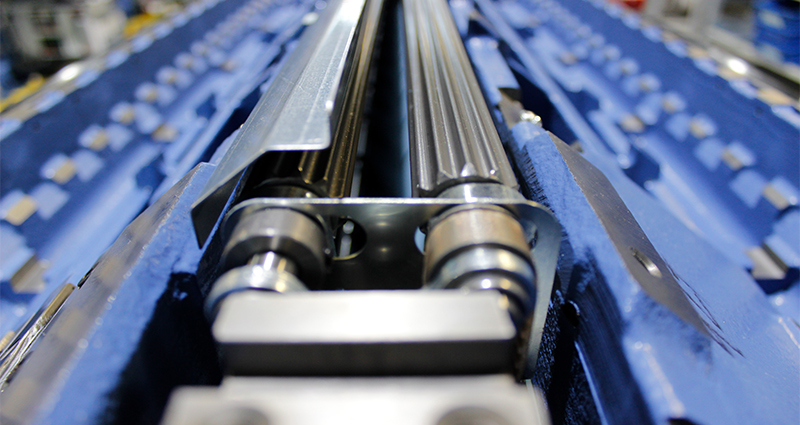

STOLL-MULTI FLEX® FABRIC TAKE-DOWN

The take-down system (variably adjustable roller segments, take-down components are freely programmable) consisting of a main take-down, upper take-down and take-down comb for fabric starts on empty needles, operates automatically.

USB PORTS

Thanks to the easy-to-reach USB port, important data can be transferred to the CMS machine quickly and easily.

CLAMPING AND CUTTING DEVICE

Thread holding via eight clamping and cutting units on each side (depending on the CMS model). Many CMS models can optionally be ordered with 2 × 16 clamping and cutting units.

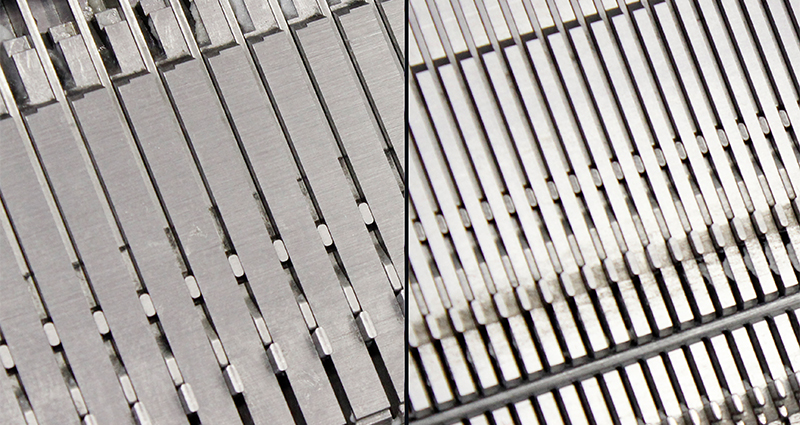

GAUGE CONVERSION

Flexible and economical adjustment of machine gauge by means of gauge conversion or needle exchange.

AUXILIARY TAKE-DOWN

Better wide fixing effect of the knitting piece.

Special Features

BELT TAKE-DOWN

Particularly for products with deep gores or with large width variation and special elastic properties

WEAVE-IN DEVICE

For reliable insertion of inlay yarns, the weave-in device is available for all systems.

Accessories

CENTRAL LUBRICATION

The automatic central lubrication supplies the needle bed with the necessary needle oil.

INTARSIA YARN FEEDERS (Not for ADF)

Swivel mounted Intarsia yarn feeders in optimum size to be slipped on easily.