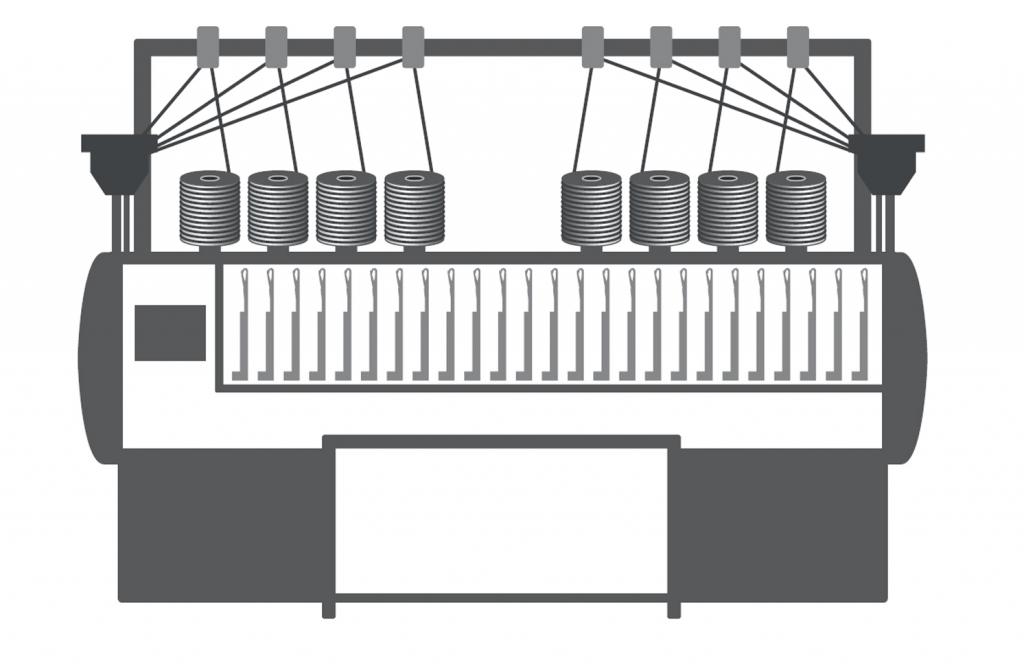

Flat knitting machines work with up to four needle carriers which are opposite one another like a V-shaped roof. As in circular knitting machines, the movement of the needles is controlled by cams. These cams are attached to the carriage of the flat knitting machine. The carriage performs a horizontal movement over the needle carriers.

Typical application examples are the manufacture of outerwear, such as pullovers, jackets, vests and accessories like collars, cuffs, caps and also 3D molded parts for technical applications like upholstery.

Flatknitting Machine Needles:

Wire butt needle

In addition to state-of-the-art flat knitting needles for latest-generation machines, Groz-Beckert continues to manufacture wire butt needles of the kind found in old, hand-operated flat knitting machines.

Links needle

Links needles, also called double-headed needles, are equipped with two loop-forming parts, located at the ends of the needle.

Latch needle without transfer function

Latch needles without transfer function are mainly employed in collar and glove knitting machines. Since very rigid collars are knit, the needle must be very stable.

Latch needle with transfer function

For complex knitted fabrics it is necessary to transfer loops from one needle to another needle on the opposite side. This requires a transfer function.

Spring-loaded latch needle with transfer function

Many errors crop up in knitting when inserting yarn and casting off loops. Precisely in these processes, spring-loaded latch needles provide additional security.

Compound needle with transfer function

Compound needles consist of two parts: the needle part and the closing element. In the loop formation process the closing element takes on the function of covering the hook in order to form another loop.

Flatknitting Machine System Parts:

Coupling parts

Coupling parts are used as connecting elements between needles and selecting jack.

Intermediate jack

The intermediate jack is used as connecting piece between needle and selecting jack. It ensures that a specified needle is securely positioned and performs the right knitting function.

Selecting jack

Secured spring force, constant reaction time and good rounding ensure a reliable functioning of the selecting elements. This prevents selection errors, thus increasing customer profits.

Press jack

During the loop formation process, press jacks ensure that the knitted fabric does not ride up.