Sewing machine needles have formed part of Groz-Beckert’s manufacturing program for over 35 years now. Whether traditional underwear, high-quality suits, shoes or technical textiles – with a product portfolio of around 3,000 sewing and shoe machine needles, Groz-Beckert offers the right product for every application.

Sewing machine needles from Groz-Beckert are always produced with the latest technology and maximum precision, and have always boasted top-notch quality. Through regular further developments and innovations, Groz-Beckert has thus established itself as a leading provider in the field of sewing machine needles.

But not just this comprehensive and top-notch product program makes Groz-Beckert an indispensable partner. A wide range of services, such as the sewing and joining service and the customer portal, top off the outstanding offering. The patented INH Quality Management developed by Groz-Beckert for handling sewing machine needles in sewing plants also reflects the innovative force of Groz-Beckert.

Product variety

Sewing machine needles come in many different types. Generally, they can be classified based on their sewing application, such as:

- Chainstitch needles (UY 121, UY 128, B 63, 149×5, 149×7)

- Lockstitch needles (DBx1, 134, 134-35, 135×17, 1738)

- Embroidery machine needles (DBxK5, 287 WKH)

- Overlock needles (B 27, UY 154)

- Blind stitch needles (29 BL, 251, 1669 E EO)

Different Needle Points:

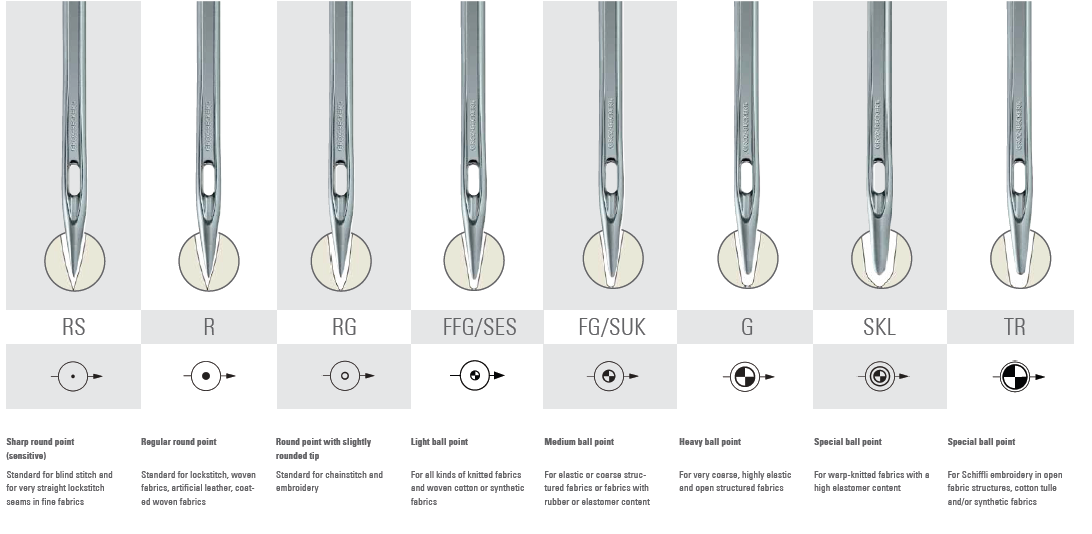

Sewing machine needles are also available in different sizes and point styles (cloth points and cutting points) to suit the relevant material to be processed.

Cloth points – also known as round points – are used to sew fabrics that are woven, knitted or felted. Due to the“rounded“ form of the point, the threads and stitches are displaced, protecting the sewing material. The selection of the right point is made depending on the textile structure, and this has a significant effect on the sewing result.

Cloth Points from Groz-Beckert

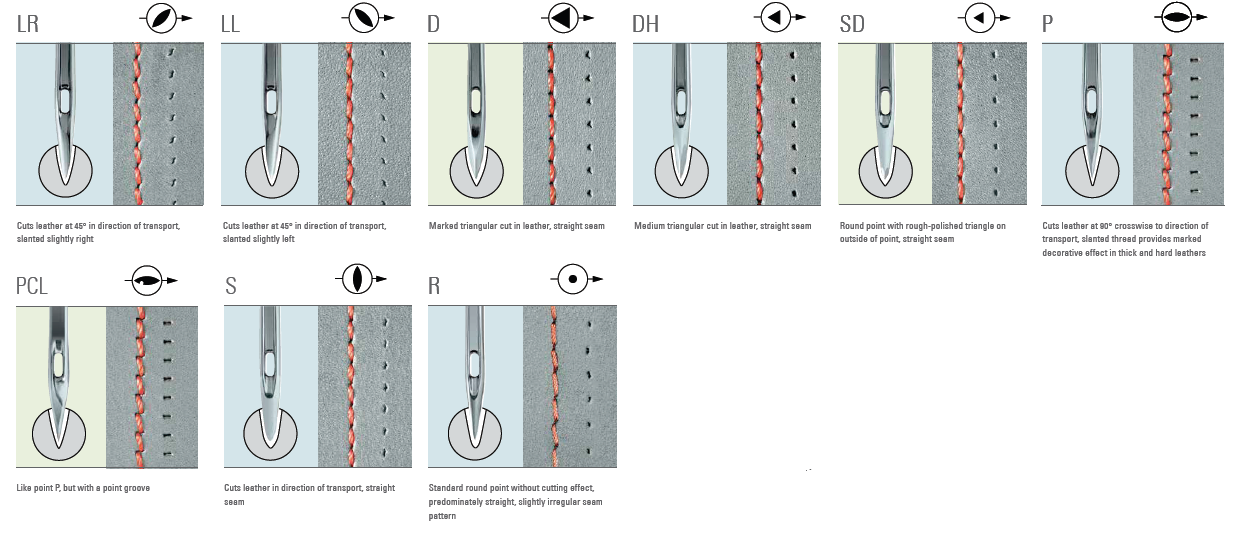

Since leather has a different longitudinal and cross structure, seam appearance will vary, depending on sewing direction, when sewing leather with a cloth point. The reason for this are the hair canals and sweat glands running in longitudinal direction. A cutting point must therefore be used to achieve a uniform seam pattern in all sewing directions. In order to stitch different-looking seams, Groz-Beckert offers a wide range of cutting points:

Cutting Points for leather processing

Groz-Beckert’s special technologies in sewing needles

GEBEDUR®

The titanium nitride coating

Demanding sewing processes, such as the stitching of hard materials or combinations of materials, often lead to premature wear of sewing machine needles.

The special GEBEDUR® coating from Groz-Beckert gives the needle a higher degree of hardness. The titanium nitride coating makes the needle more wear-resistant, particularly protecting against damage around the point and eye. This extends the service life of the needle, ultimately leading to consistently high seam quality and increased productivity.

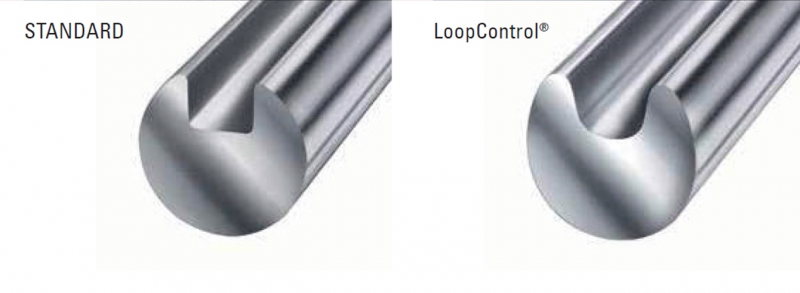

Loop Control®

The innovative needle geometry

A perfectly formed loop is the basis for flawless and high quality seams, which are significantly influenced by the geometry of the sewing machine needle employed.

Groz-Beckert’s unique Loop Control® needle geometry is an intelligent solution for lockstitching and chainstitching. Secure loop formation minimizes skipped stitches and the sewing thread is treated with maximum care thanks to the special geometry of the groove. Moreover, the Loop Control® geometry of the needle gives it better stability and the needle deflects less, leading to less needle breakage and less damage to points.

All told, the Loop Control® geometry boosts the stability of the sewing process, thereby leading to increased productivity.

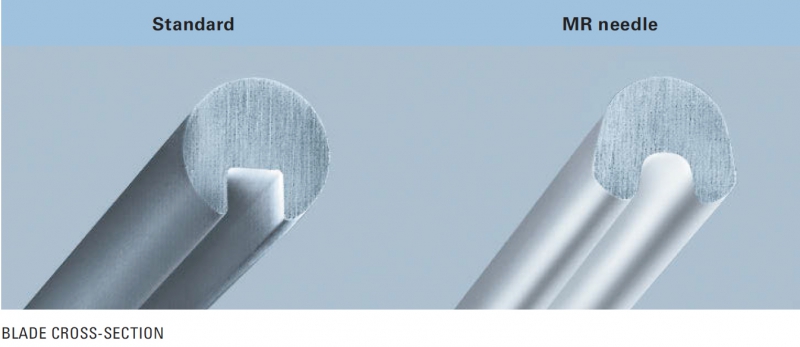

The MR needle

For automatic sewing processes with multi-directional function

Automated sewing systems are becoming more popular in the sewing industry. Yet loop formation can often become unstable, especially when changing sewing direction.

Standard needles frequently reach their limits in multi-directional applications. This can result in sewing problems such as needle breakage, sloppy seams (due to skipped stitches or thread breakage) and damage to material.

The MR needle from Groz-Beckert has been fine-tuned to meet these challenges. The asymmetric thread guiding area in the eye facilitates – also when changing sewing direction – stable loop formation. The very deep and long scarf allows the hook or looper to be positioned very close to the needle for optimum thread protection.

This provides high security against skipped stitches, reducing needle and thread breakage.

The Groz-Beckert special application needles

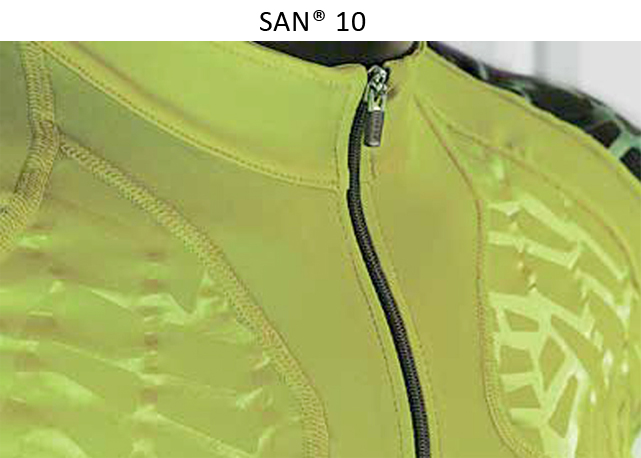

The special application needles – SAN® – from Groz-Beckert come into their own wherever the demands made on the needle exceed the standard due to the nature of the sewing application. SAN® needles have a geometry optimized to the specific application, resulting in greater process reliability. They reflect Groz Beckert’s exemplary standard of innovation.

The sewing machine needle for technical textiles

The benefits:

- Increased needle stability

- safeguard against skipped stitches

- Gentle handling of the sewn fabric

- Uniform seam appearance

- Use of thicker sewing threads

- High protection against needle wear

- Increased productivity

- Reduced production costs

Applications:

- Airbags

- Carrying straps

- Car seats

- Upholstered furniture

- Protective clothing

- Sun protection systems

processing medium-heavy and heavy textiles, such as denim

The benefits:

- High security against skipped stitches and thread breakage

- Less needle breakage due to increased stability

- Heavier sewing threads can be used

- High protection against point wear thanks to the GEBEDUR® coating

- Low needle consumption due to longer service life

- High process reliability

material-protecting processing of fine and very fine textiles

The benefits:

- Improved seam quality, while protecting the material at the same time

- Prevention of skipped stitches

- Less thread breakage

- Possibility to use thicker sewing threads using the same needle size

2-needle decorative seams

The Benefits

- Even seams

- Perfect appearance